In many different types of settings, redundant automation technologies are key to keeping processes running reliably and smoothly. In hospitals for example, where consistent power supply is vital in the truest sense of the word. Smart circuit controls will immediately activate emergency generators so that health emergencies can still be attended. Or in large data processing centers, where the temperature needs to remain cool enough for the servers to operate. Automated control switches will meter and adjust the cooling system to guarantee a perfect “working climate” for the servers.

Finding the right combination of hard- and software is key

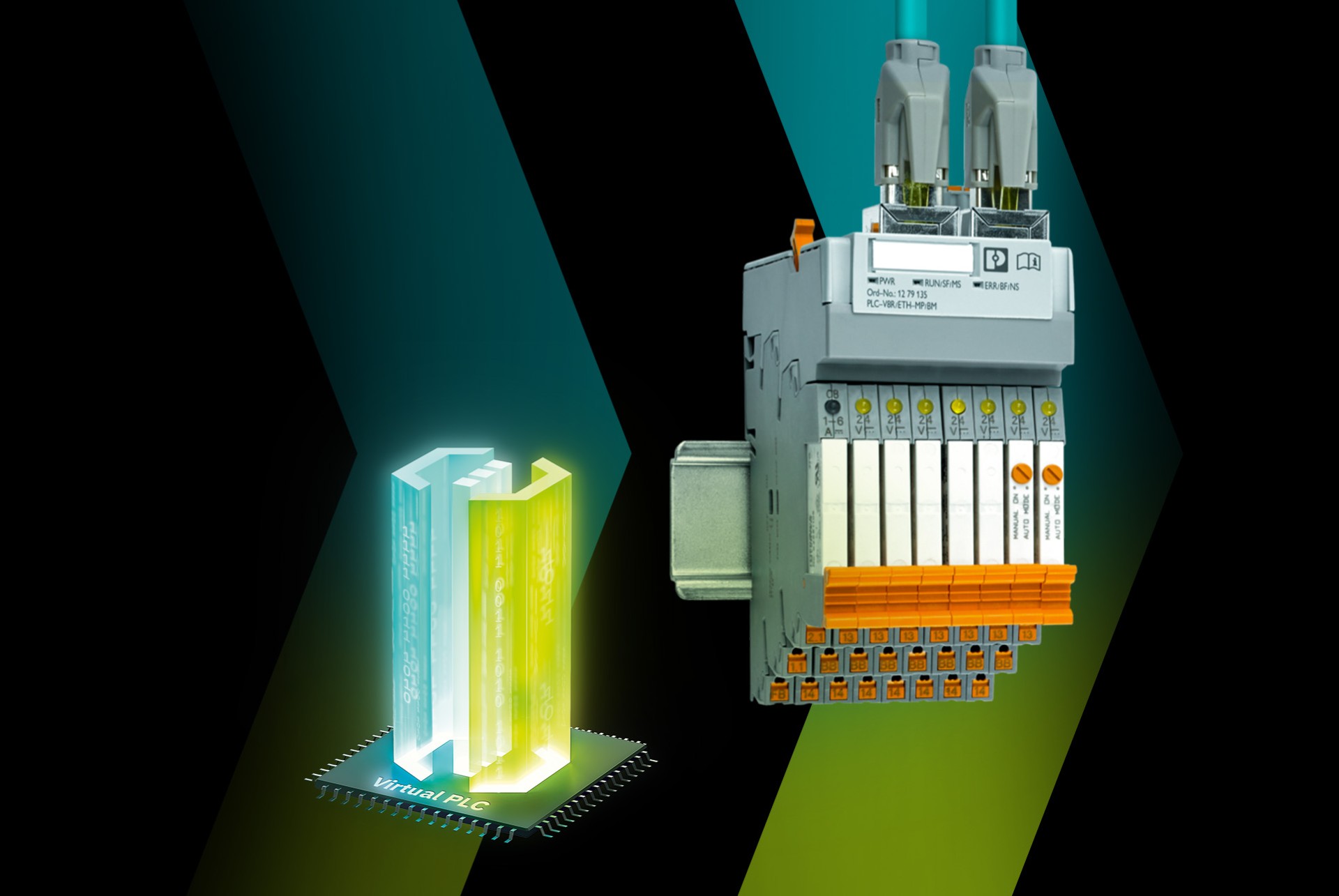

When it comes to setting up proper solutions for redundant processes, it is very important to find the right combination of hardware (in most cases the best suiting PLC) and software (in most cases specific codes or apps for the particular task). PLCnext Control by Phoenix Contact is the hardware of choice in countless redundant automation systems around the globe. Mainly for two convincing reasons: Firstly, because they are extremely reliable. PLCnext Control is built to perform no matter what the environment or circumstances. And secondly, because programming them is not only very simple but also very versatile thanks to PLCnext Technology. Virtually all existing control-programming apps can be used to adjust the devices for their specific task. And thanks to an open platform approach, PLCnext Control is compatible with merely any imaginable code and programming language.

A good example for the successful implementation of a redundant automation setup with PLCnext Technology is the traffic control system in Belgian highway tunnels. A highly reliable solution was needed that would monitor and analyze the current traffic situation in real-time and then automatically carry out processes accordingly when needed. There are 15 different scenarios, which the system can differentiate. For instance, if an accident occurs inside one of the tunnels, warning signals are instantly activated plus the speed limit is reduced within milliseconds. This immediate response is key to preventing other drivers from getting into a hazardous situation or even crashing into the accident themselves. If necessary, the automated system can even close the gates at the entrance of the tunnel and thus shut down traffic completely.

Openness of programming offers many options

When the system integrators “Equans” planned the setup for the Belgian tunnel authorities, they were delighted by the openness with which they could program the PLCs. Thanks to its versatility the PLCnext Engineer editor allows for programming either via IEC 61131 or HLL or pretty much any other code or language. In addition to that the debugging tools within PLCnext Engineer helped eradicate any occurring errors and thus enabled a swift programming process. By including code from GitHub in the setup, it became even easier to track and resolve bugs within the system.

Another big advantage of PLCnext Technology played into the hands of the developers: Its supreme scalability was very helpful in implementing and expanding the control system. While already existing devices and controls could be included into the architecture, it was also fairly simple to transfer the setup to other tunnels once it was installed into one of them. Originally the redundancy function was carried out by using Applicative System redundacy (ASR – see introduction in the PLCnext Info Center). Later it was changed to be managed through a high-performance redundancy controller (see description in the PLCnext Info Center).

The Belgian traffic authorities are benefitting greatly from the fact that the OPC server allows for seamless exchange of information between the automated system and the traffic control headquarters. A web-based monitoring and maintenance tool enables an effortless remote supervision of the system. Now the technicians can simply use a tablet or notebook to check and adjust the traffic control setup from anywhere at any time.

As the implementation and maintenance of the tunnel traffic control system was so convincingly convenient, the Belgian traffic authorities are planning on utilizing PLCnext Technology to perform even more tasks within the tunnel. Soon, there will be an automated system in place to control not only the ventilation but also the lights inside the tunnel. Also, there are sensors being tested to monitor any road irregularities to ensure a smooth ride for all vehicles. When reliable solutions are needed for redundant automation tasks, PLCnext Technology is a safe bet.