The open Ecosystem for Industrial Automation

As innovation cycles shorten, automation systems must be able to be adapted ever more quickly in the future.

For many companies this means a change in thinking, changes in processes and other approaches. For example, know-how will have to be purchased more often in the future and many further developments and innovations will be created primarily by communities and the creativity of many idea providers. Flexibility and efficiency will become the most urgent requirement for us all. That means, reuse what has already been developed and proven, and maximum openness. Openness in thinking and openness of systems.

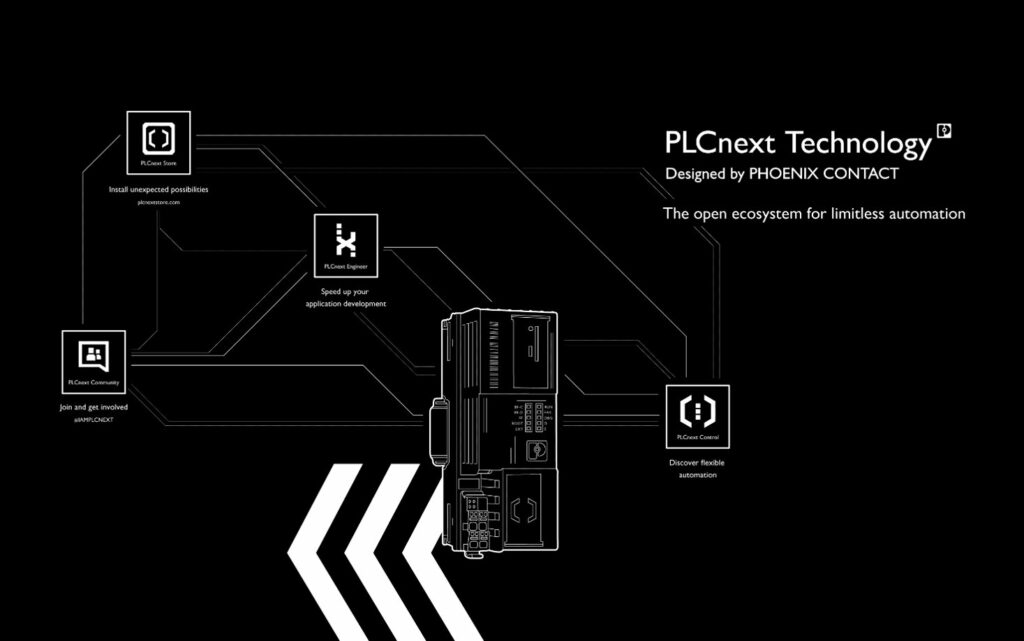

That’s why we have developed PLCnext Technology. PLCnext Technology is the open ecosystem that expands the use of a PLC in ways that will change the future of industrial automation.

PLCnext Technology

Enhanced development

Enhanced development

Enhanced development

Connected coworking

With PLCnext Technology, several developers from different generations can work on one controller program independently of each other, using different programming languages. Thus, you can develop complex applications quickly using the advantages of the classic PLC world and the openness and flexibility of PLCnext Technology.

Enhanced Performance

Enhanced Freedom

Enhanced Connectivity

Enhanced Convenience

Enhanced development

Enhanced development

Connected coworking

With PLCnext Technology, several developers from different generations can work on one controller program independently of each other, using different programming languages. Thus, you can develop complex applications quickly using the advantages of the classic PLC world and the openness and flexibility of PLCnext Technology.

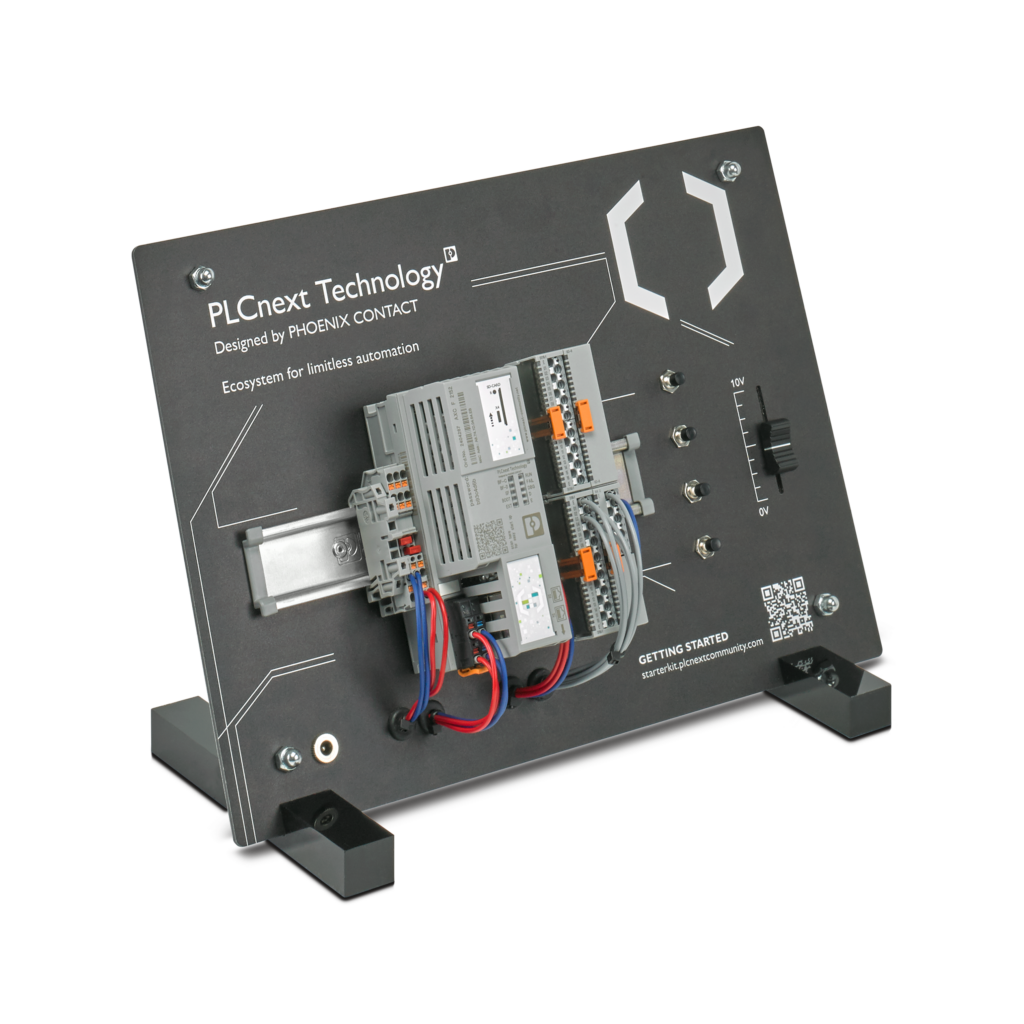

Hardware for PLCnext Technology

PLCNEXT STORE

For you as a software developer, the PLCnext Store is the ideal platform to offer your solution and gain access to a new customer base.

SOFTWARE

Your engineering environment

It combines all of the basic functions needed for configuration, programming in accordance with IEC 61131-3, visualization, and diagnostics. In addition, this software also allows you to easily connect high-level language code to the standard application. PLCnext Engineer is available for download free of charge. You can use additional add-ins as well as a broad variety of software applications from the PLCnext Store for a wider range of functions.

OUR COMMUNITY

#plcnext #iamplcnext

Stories from users for users

Get help and exchange ideas

Meet our experts live online

Join us at an event near you

Get started with our interactive tutorials

Download interactive ePaper

Check out the first PLCnext Technology interactive ePaper now and find all the information you need in one place. The ePaper is available for free in German and English.

In this e-paper you will find buttons that allow further interaction. Get inspired by exciting use cases, have a closer look at our hardware with 3D images, get more detailed information about products in our webshop, or learn more about all four parts of the ecosystem. There is also a wide range of further links and embedded videos to all your favorite topics.