In many industrial environments, companies are exploring Predictive Maintenance Edge AI to make better use of the data they continuously collect—data that is often left unused or only evaluated retrospectively.

With the VL3 UPC 2440 EDGE and the MLnext software suite, companies can implement AI-based anomaly detection directly on the shop floor. The process is straightforward and does not require prior knowledge in machine learning or programming.

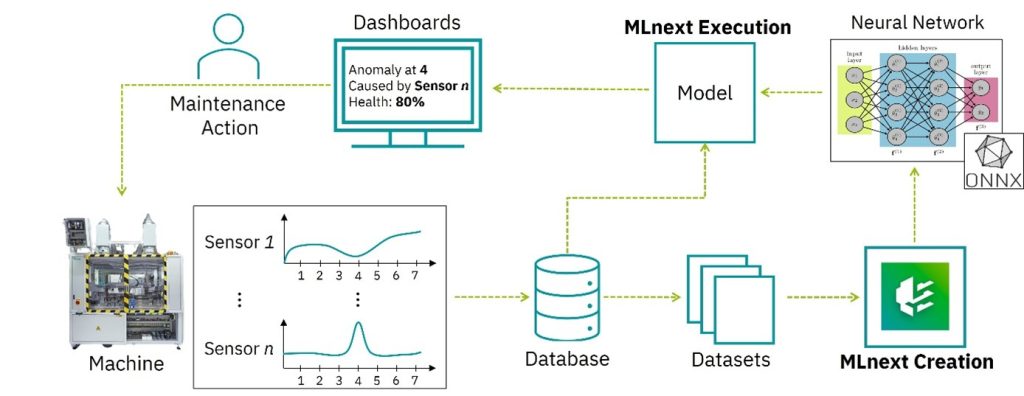

Step 1: Collecting Data at the Edge

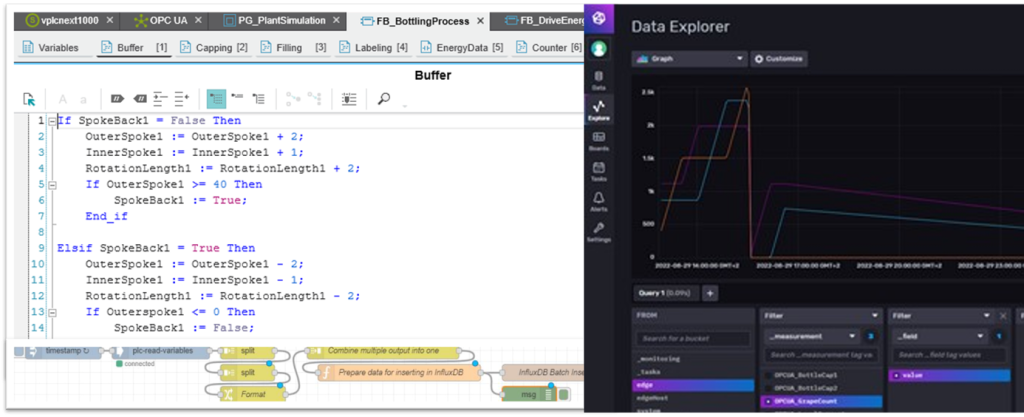

The foundation of any intelligent application is reliable data. The VL3 UPC 2440 EDGE collects and stores data from machines, sensors, and PLCs locally. It supports widely used industrial protocols such as PROFINET, MQTT, Modbus TCP, and Ethernet IP. Users can configure and manage data flows using tools like PLCnext Engineer or Node RED.

For time series storage, InfluxDB can be installed directly on the device via the PLCnext Store or Ubuntu Store. Consequently, this creates a robust local data environment that is ready for further analysis.

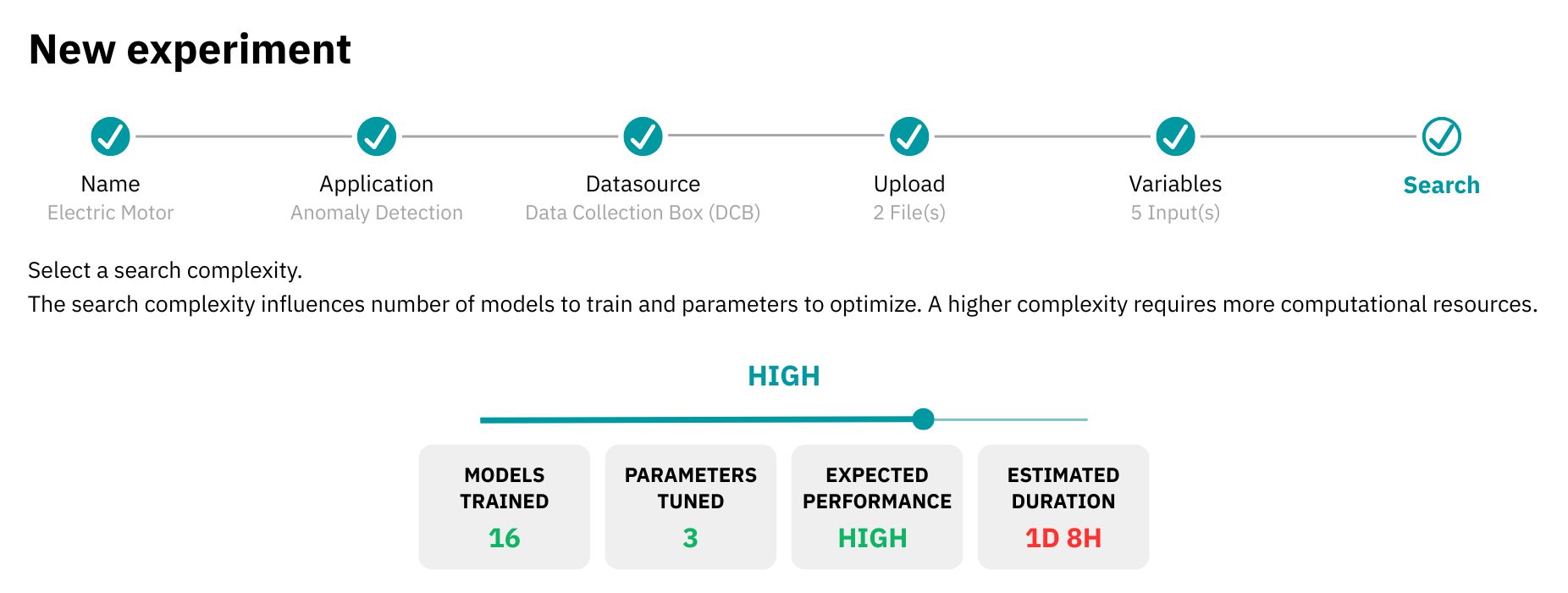

Step 2: Training an AI Model with MLnext Creation

Once a sufficient amount of data has been collected (typically over several weeks or months) it can be exported from InfluxDB and used to train an AI model with MLnext Creation on a PC.

The software is intuitive. Users select the relevant variables and define the desired optimization level. As a result, the system automatically handles all other steps, including data preprocessing and model training. This makes it possible to create models for anomaly detection, process optimization, or condition monitoring without writing any code.

For those who enjoy digging into data but prefer to avoid complex algorithms, MLnext offers a practical and accessible solution.

Step 3: Deploying the Model on the Edge

After training, users deploy the model back to the edge device using MLnext Execution, available in the PLCnext Store. The software executes the model at defined intervals, compares live data with the trained patterns, and detects deviations in real time.

A web interface and REST API allow for monitoring and integration into existing systems. Since the data remains on the device, the system operates independently of external infrastructure and can respond immediately to anomalies.

This enables early detection of wear, sensor drift, or unexpected process changes—helping to reduce downtime and improve operational stability.

Step 4: Acting on Insights

When the system detects anomalies, it can trigger alerts, visualize deviations, or initiate automated responses. This flexibility allows companies to tailor the solution to their specific needs, whether through manual intervention or integration into existing control systems.

The result is a more resilient and responsive production environment that benefits from data-driven decision making.

In a nutshell

Edge computing and artificial intelligence are no longer reserved for large-scale or experimental projects. With tools like the VL3 UPC 2440 EDGE and MLnext, companies can implement intelligent applications directly at the machine level. The process is practical, scalable and designed to deliver real value in everyday industrial operations.