Automation of hydrogen energy storage is revolutionizing how remote sites manage renewable energy. Discover how Endua, in partnership with Phoenix Contact, developed a scalable and safe hydrogen-based power solution using PLCnext Control.

In remote regions where access to reliable energy is limited, traditionally diesel generators have long been the default solution—despite their environmental and operational drawbacks. The Australian start-up Endua is changing that with a modular hydrogen energy storage system designed specifically for off-grid applications. By integrating PLCnext Control and safety technology from Phoenix Contact, Endua has created a smart, scalable, and sustainable alternative that ensures long-term energy availability, even during extended periods without sun or wind. This article examines how automating hydrogen energy storage can pave the way for a cleaner future for off-grid industries and communities.

The Challenge: Reliable Energy for Remote Locations

Remote communities, mining operations, and off-grid infrastructure often struggle with energy reliability. Traditional solutions like diesel generators or lithium-ion batteries either pollute or fall short in long-term storage. Endua’s mission: to provide a clean, long-duration energy alternative that can be deployed anywhere—without compromising performance or sustainability.

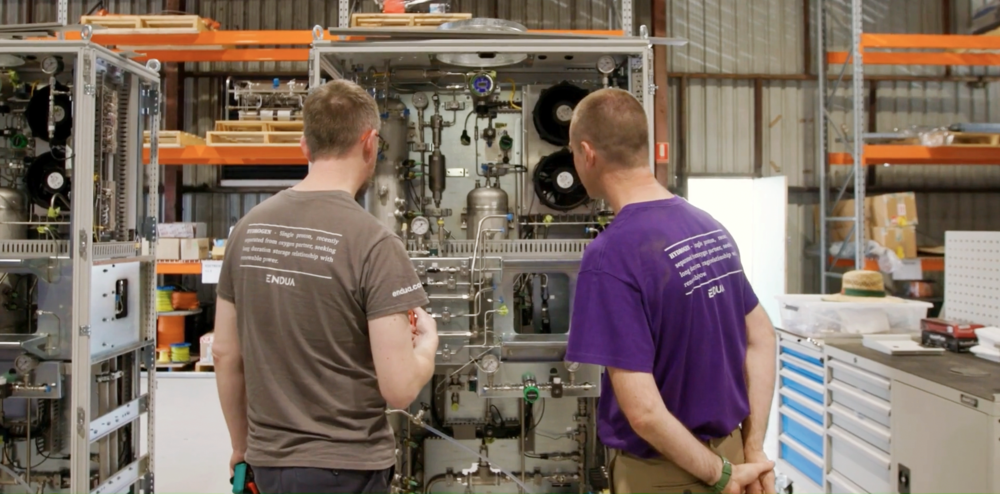

Automation of Hydrogen Energy Storage in Action

At the heart of Endua’s solution is a modular hydrogen power bank. Using renewable energy, water is split via PEM electrolysis into hydrogen and oxygen. The hydrogen is stored and later converted back into electricity using fuel cells. Unlike lithium-ion batteries, this system can store energy for several days—making it ideal for locations with intermittent renewable generation.

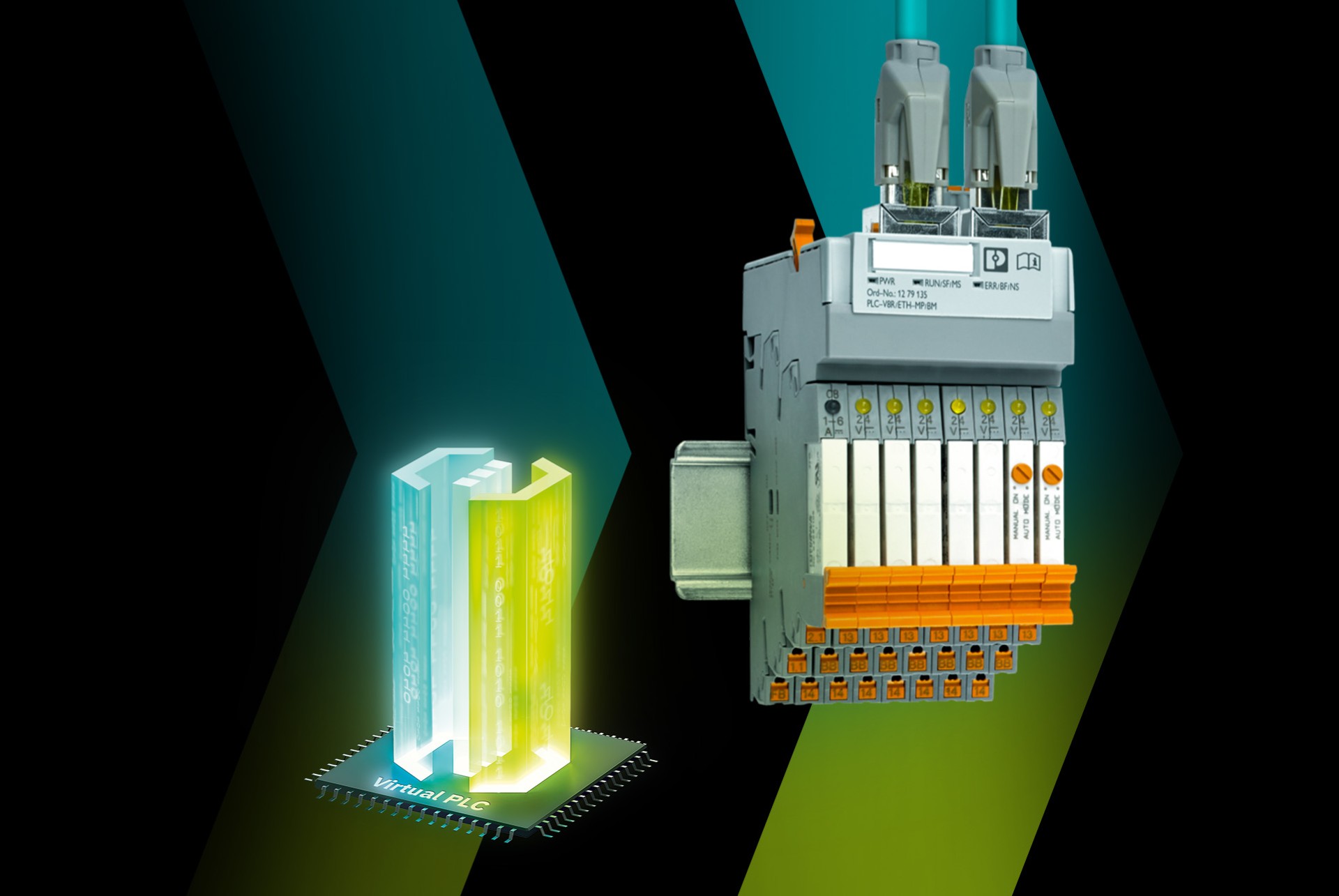

Modular, Scalable, and Safe: The Role of PLCnext Control

To ensure precise control and safety, Endua turned to PLCnext Control and PSRmodular safety technology from Phoenix Contact. The PSR-configurable safety modules come with TÜV-certified software, which allowed Endua to develop the safety logic with minimal programming knowledge, and a modular design allows the controllers to be easily adapted to meet requirements.

- Scalable system design

- Seamless integration of control and safety

- Global support and consistent quality through a single supplier

The result is a flexible, high-performance control system that adapts to various energy demands—from small communities to industrial-scale applications.

Cloud-Based Monitoring and Predictive Maintenance

Endua’s system is not only smart on-site—it’s also connected to the cloud. Using ‘Inductive Automation’s Ignition SCADA‘ and Phoenix Contact’s industrial PCs, the system collects and transmits performance data via MQTT. This enables:

- Remote monitoring of all components

- Predictive maintenance based on real-time data

- Reduced downtime and service costs

This level of connectivity is essential for systems deployed in hard-to-reach areas.

Benefits at a Glance

- Long-term energy storage for days, not hours

- Modular and scalable design for flexible deployment

- Integrated safety and control in one platform

- Cloud-based monitoring for predictive maintenance

- Reduced total cost of ownership through simplified architecture

Looking ahead: Next-Gen Hydrogen Systems with Integrated Functional Safety

Safety is a critical factor in hydrogen-based energy systems. In its second-generation test system, Endua will take has taken a major step forward by integrating control, safety, and IPC technology into a single PLCnext Control unit. This unified approach simplifies the system architecture, reduces the potential for errors, and lowers the total cost of ownership.

Using the PLCnext Engineer environment, engineers can program, test, and modify both automation and safety logic on one platform. This not only accelerates development but also ensures consistency and compatibility between safety and control functions. The TÜV-certified safety modules monitor critical parameters such as hydrogen leaks and gas detection, providing a robust safety layer for remote and industrial applications. As Eduardo Aruda, Product Manager at Phoenix Contact Australia, explains: “The integrated PLCnext Control solution with functional safety opens up numerous advantages compared to the original power bank configuration. Instead of managing two separate systems, engineers now benefit from a streamlined, unified environment.”

Conclusion: A Smart Step Toward Sustainable Energy Independence

By combining hydrogen technology with advanced automation, Endua and Phoenix Contact are delivering a future-ready solution for off-grid energy. Their collaboration demonstrates how intelligent control systems can unlock the full potential of renewable energy—anywhere in the world.

More Information

Find more information on this interesting hydrogen energy storage solution at the Phoenix Contact Website.

Are you interested in reading more about our newest green automation project? Feel free to explore our latest use case ‘Automating Green Hydrogen with PLCnext Technology‘.