Modern data centers are under increasing pressure: more performance, higher availability, maximum security – at lower costs. Classic PLC infrastructures are reaching their limits. The solution: Virtual PLCnext Control and an open, software-based automation concept that intelligently connects IT and OT.

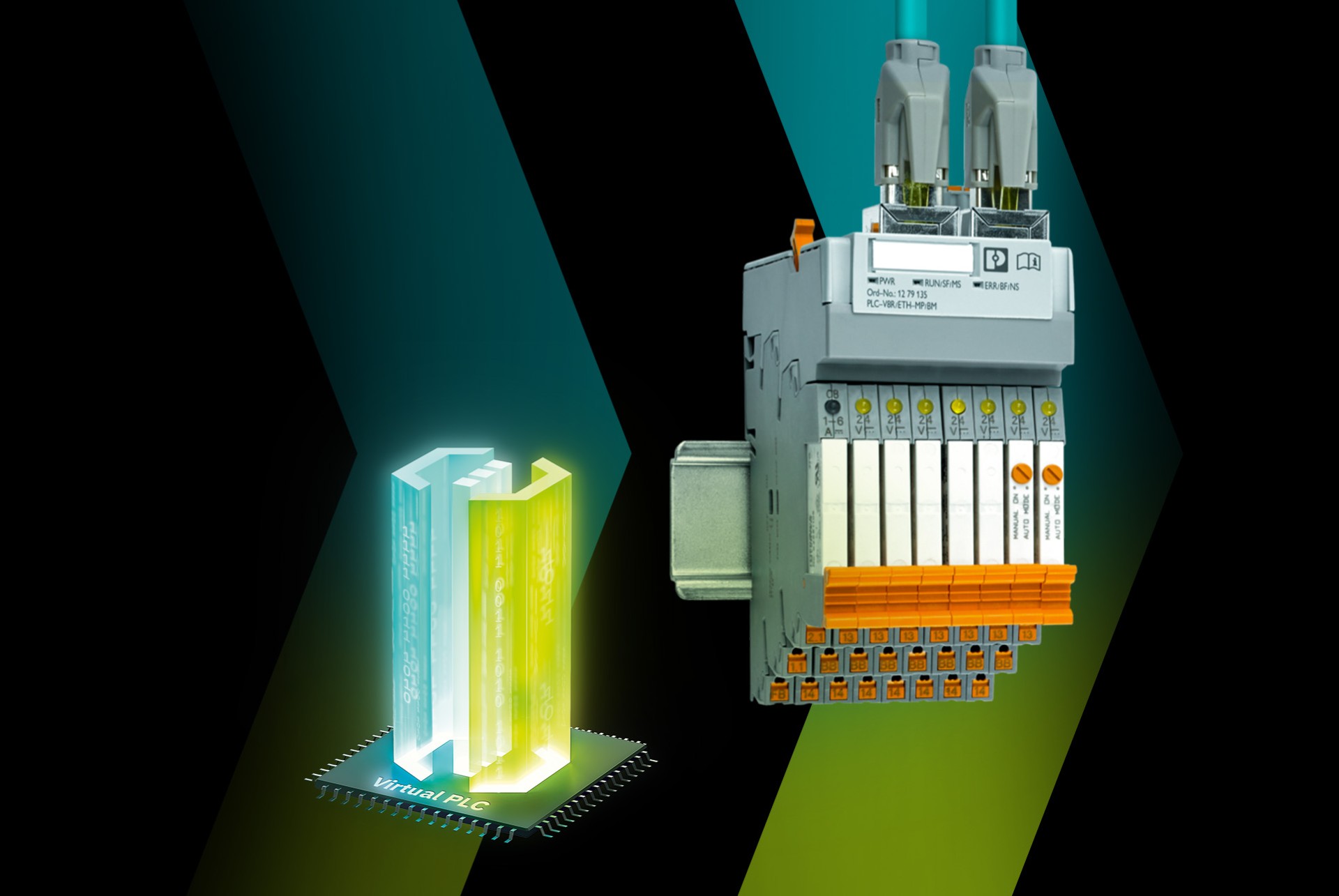

Virtual PLCnext Control – PLC rethought

Virtual PLCnext Control runs as a software (OCI)-container on standard servers or industrial PCs – without any PLC hardware. Advantages:

- Hardware independence: Operation on existing IT infrastructure.

- Central scalability: Controllers can be rolled out and updated centrally.

- Cost reduction & reliability: Less hardware, more redundancy.

- IT/OT integration: Industrial protocols such as PROFINET and OPC UA are supported.

PLCnext Engineer – Everything in one platform

PLCnext Engineer is the central tool for project planning and programming:

- IEC 61131-3 compliant with high-level language integration.

- Uniform interface for hardware, networks, programs, and visualizations.

- Expandable & secure: Add-ins, debug tools, and certified safety functions.

Remote relay system – Flexible switching on site

The PLC-INTERFACE Ethernet Gateway offers up to 56 channels in a compact design:

- Modular and space-saving: Ideal for decentralized applications.

- Multi-protocol capable: PROFINET, EtherNet/IP, Modbus TCP.

- Robust & low-maintenance: For continuous operation in data centers.

Just follow the link for more information about the system.

Practical example: EPMS – Electrical Power Monitoring System in the data center

The Virtual PLCnext Control takes over the central logic on, for example, a panel PC. In the EPMS in particular, visualizations are of central importance in addition to the control task.

The combination of HMI and vPLC on the panel PC saves additional space and components.

For the first time, the remote relay system integrates analog and digital signals from sensors and actuators into the control level in a modular and decentralized manner.

The combination of these two systems can generate maximum impact in terms of cost efficiency and space savings, not only in this practical example.

Conclusion

Comparable solutions, especially for the EPMS (Electrical Power Monitoring System) in data centers, rely on classic software environments, additional control hardware, and complex IO systems for the integration of simple signals.

By combining Virtual PLCnext Control with a panel PC, the openness of PLCnext Technology, and the innovative approach of the remote relay system, you can make your data center future-proof – scalable, flexible, and efficient.

You want to read more about Virtual PLCnext Control? Just follow this Link and get more information.