MathWorks

Who is MathWorks?

MathWorks® is the leading developer of mathematical computing software for engineers and scientists. The flagship products, MATLAB® and Simulink®, help innovators design and bring their ideas to life.

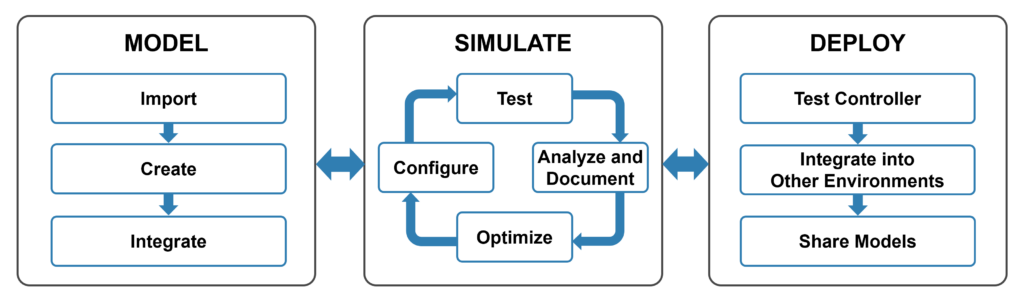

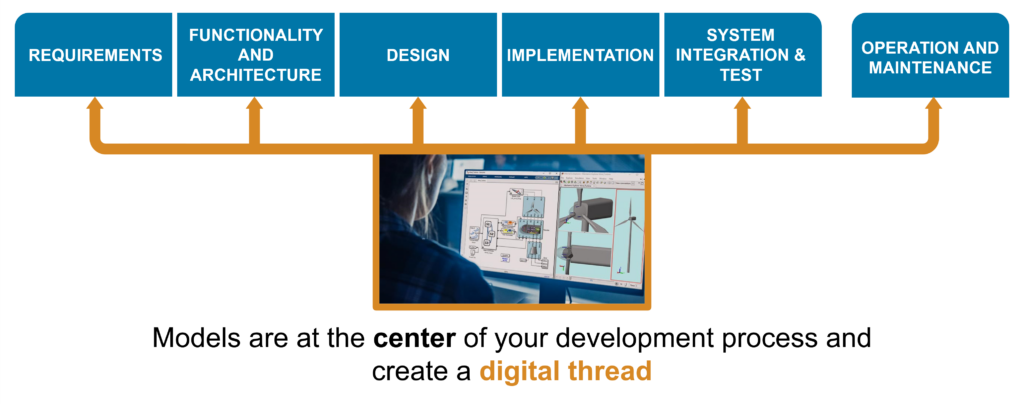

Engineers use Model-Based Design with MathWorks MATLAB and Simulink to address the growing complexity of modern automation solutions. This systematic use of models throughout the entire development process helps you to:

- Try new ideas and perform fast repeatable tests with modeling and simulation

- Eliminate manual steps and reduce human error by automating key steps such as reporting, coding, and verification

- Create a digital thread with traceability from requirements and system architecture to component design and tests

- Perform predictive maintenance, detect faults, and optimize the system in operation using models as digital twins

You can use Model-Based Design with MATLAB and Simulink to shorten development cycles and reduce your development time by 50% or more.

Industrial and mechatronic applications of MATLAB and Simulink include:

- Control design, and rapid controls prototyping

- Virtual Commissioning, virtual prototyping, and multiphysics simulation

- Hardware-in-the-Loop testing

- AI-based predictive maintenance, anomaly detection, visual inspection, and control

- Manufacturing and process data analytics

MathWorks and PLCnext Technology

Simulink models can be automatically converted into device-specific code for PLCnext Control, using PLCnext Target for Simulink. The executable code is compatible with all standard controllers in the PLCnext Control product family. The software is provided as an add-on to the integrated development environment PLCnext Engineer.

Using Model-Based Design and the simulation capabilities of Simulink, PLCnext Target for Simulink ensures a structured model implementation for PLCnext Control. Executable code is generated automatically. With straightforward import functionality and configuration options, the model can be executed simultaneously alongside programs developed in IEC-61131-3. With PLCnext Technology, Simulink can even be deployed with other high-level programming languages under real-time conditions. The parameters of the model can be monitored and optimized during execution via Simulink external mode, enabling maximum performance of your application.

You want to learn more about PLCnext and Simulink? Then see this user presentation about implementing a PLCnext-based turbine control system in Simulink.